NASA's Centennial Challenges: 3D-Printed Habitat Challenge

The 3D-Printed Habitat Challenge was a NASA’s Centennial Challenges program competition to build a 3D-printed habitat for deep space exploration, including the agency’s journey to the Moon, Mars or beyond. The multi-phase challenge was designed to advance the construction technology needed to create sustainable housing solutions for Earth and beyond. The competition, completed in 2019, awarded a total of $2,061,023.

👉• Youtube: TopTechTopic - Click Here & Subscribe !!

- Phase 1, the Design Competition, required teams to submit architectural renderings and was completed in 2015. ($50,000 prize purse/$40,000 awarded)

- Phase 2, the Structural Member Competition, focused on material technologies, requiring teams to create structural components. It was completed in 2017. ($1.1 million prize purse/$701,000 awarded)

- Phase 3 the On-Site Habitat Competition, completed in 2019, challenged competitors to fabricate sub-scale habitats, and had five levels of competition – three construction levels and two virtual levels. For the virtual levels, teams used Building Information Modeling software to design a habitat that combined allowances for both the structure and systems it must contain. The construction levels challenged the teams to autonomously 3D-print elements of the habitat, culminating with a one-third-scale printed habitat for the final level. ($3.15M prize purse/ $2M awarded)

➡️ https://www.nasa.gov/directorates/spacetech/centennial_challenges/3DPHab/about.html

Foster + Partners

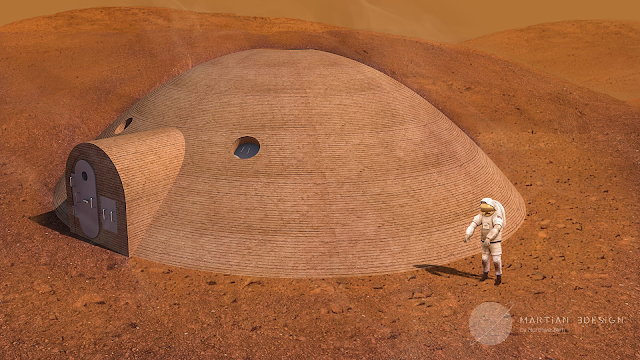

Foster + Partners New York’s design for a modular habitat on Mars has been shortlisted amongst 30 finalists for the 3D Printed Habitat Challenge organized by America Makes and NASA.

The design outlines plans for a settlement on Mars constructed by an array of pre-programmed, semi-autonomous robots prior to the eventual arrival of the astronauts. The design of the habitat – carried out in collaboration with industrial and academic partners – envisions a robust 3D-printed dwelling for up to four astronauts constructed using regolith – the loose soil and rocks found on the surface of Mars. The proposal considers multiple aspects of the project from delivery and deployment to construction and operations. The habitat will be delivered in two stages prior to the arrival of the astronauts.

NASA Awarded Five Teams $100,000 in 3D-Printed Habitat Competition as below:

The Winners

5. Northwestern University

The fifth place was awarded to a team from Northwestern University, in Evanston, Ill., for its straightforward 3D-printing process. The housing pod features an inflatable, dome-shaped pressure vessel that provides the form over which the 3D printer will output an outer parabolic dome.

4. SEArch+/Apis Cor

New York–based Space Exploration Architecture (SEArch+) and Russian hardware startup Apis Cor were awarded the fourth place for their X-House proposal, a dual-shell housing module inspired by Alvar Aalto's Church of the Assumption of Mary, in Riola di Vergato, Italy. Constructed from materials harvested from the Martian surface, the X-House is designed to protect the residents from galactic cosmic radiation.

3. Kahn Yates

A team made up of Detroit-based architecture firm Albert Kahn Associates and Jackson, Miss., office of Yates Construction came in third place with a proposal designed to withstand the red planet's inhabitable climate and dust storms. The proposal features a five-axis print arm that would extend from the top of a prefabricated core to print the module's foundation and perforated concrete shell using local materials. Concurrently, secondary printing nozzles will begin making a protective shell using high-density, petroleum-based polyethlene thermoplastic that is known for its high strength-to-density ratio.

2. AI. SpaceFactory

The second place went to New York–based AI. SpaceFactory for its Marsha habitat, a vertical, double-shell, cylindrical structure 3D printed with "a vertically telescoping arm attached to a stationary rover," according to the team's website. By mixing basalt fiber extracted from Martian rocks with biodegradable thermoplastic derived from plants grown on Mars, the team has developed a recyclable printing material.

1. Team Zopherus

First place was awarded to a team from Rogers, Ark., for its Zopherus modular habitat. The design features an autonomous moving robot with an integrated printer chamber that seals to the ground and 3D prints hexagonal structures in its pressurized interior cabin, using materials extracted from the Martian surface, all without any human interference.

#NASA #marshabitat #3dprintedhabitat

0 Comments